It is important to test the type of adhesive before using the high-temperature resistance label stickers. To see whether it’s water-based or hot-melt glue. Some adhesives will react chemically with certain substances.

For example, self-adhesive stickers used as labels can contaminate certain special fabrics under a certain condition. Some stickers that require temporary stickiness will create long-lasting stickiness under exposure conditions. On the contrary, some stickers that require long-lasting stickiness will lose their viscosity on certain surfaces.

Some customers have the feedback that the label is not very sticky. The reasons are complex and diverse. Some customers who lack of industry knowledge will think that the quality of the stickers is not good. In fact, our self-adhesive label materials are from well-known manufacturers, there is no quality problem. Some customers may not clarify the stickiness requirements or do a trial test before pasting, it may lead to its viscosity did not meet customers’ ideal requirements.

1.Initial adhesion: the common one is the rolling ball method. Fix the adhesive side up on an inclined surface, then push some standard steel balls with different sizes slid down from the top. The larger steel ball can be stuck, the greater initial adhesion it has.

2.Permanent adhesion: use labels to stick two standard steel plates with hooks, then hang one steel plate on the fixed frame, and put 2kg weight on the other end to see how long the steel plate below will not fall down, calculating how long it can last.

3. Stripping force: Stick the label on the standard steel plate, remove the label at a constant speed with the instrument, the force used by the instrument is the stripping force of the sticker.

The common sense of how to select high-temperature resistance self-adhesive label manufacturers, the following is the 10 tips for you:

1.According to the adhesive surface material of the product

Our labels are self-adhesive and may be stuck on the surface of various materials, such as glass, metal, cardboard and plastic. And plastic can be further divided into polyvinyl chloride and high density polyethylene. Tests showed that different labeling surface had a significant effect on performance. Therefore, when choosing self-adhesive label, we must decide what kind of material self-adhesive label to choose according to the adhesive surface which our products need to stick.

2、According to the shape of the product adhesive surface

The surface of labeled item can be divided into plane one and curved one. If the labeling surface has a certain arc (for example, The surface of the medicine bottle less than 3 cm in diameter), it may need the face-stock has good adaptability or the glue is high-tack.

3、According to the cleanliness of the adhesive surface of the product

Self-adhesive material is most suitable for the clean, dry, oil and dust free label substrate surface, if it is other types of substrate, please choose other professional label paper.

4、According to environmental conditions

Labeling environment and temperature will affect the characteristics of adhesives, such as multi-water or multi-oil environment. Self-adhesive labels need to be pasted under cold, hot, humid or room temperature conditions.Whether the sticker is exposed to the environment below the freezing point, whether it is used outdoors, under high temperature, humidity or ultraviolet light, and whether it is close to the high temperature of the car engine and other conditions need to be considered. Therefore, appropriate label paper should be selected according to different environmental conditions. For example, PCB circuit board furnace label in the electronics industry must be selected for high temperature resistant adhesive(maximum temperature 350℃).

5、According to the characteristics of the label adhesive

In terms of the performance of adhesives, they can be divided into two categories: permanent adhesive and removable adhesive. Permanent adhesive is difficult to remove, its adhesive performance is strong. Removable adhesive is easy to remove, and the adhesive performance is not as good as permanent adhesive.

6、According to the printing and processing methods

In the selection of different printing methods (such as flexography printing, letterpress printing, offset printing, thermal transfer and laser printing) and processing methods (such as roll to roll, roll to sheet, folding into paper, sheet to sheet) before determining the adhesive material, should be tested in the same printing, processing and labeling conditions. The choice of face-stock depends on the printing method and the final customer requirements. High-quality printing certainly needs smooth paper and excellent internal quality self-adhesive materials. Thermal transfer printing requires the facestock is special smooth and stain resistance paper.

7、According to the storage time you need

Different products and different customers have different storage time for self-adhesive labels, some require for a long time, other require may be temporary, so we need to decide and choose according to our own requirements for self-adhesive labels, so as not to waste our own financial resources.

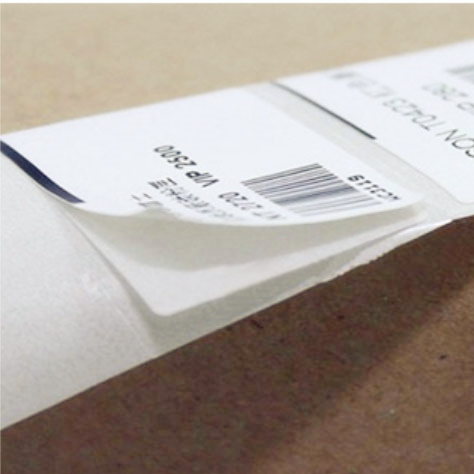

8、Pay more attention to excessive glue phenomenon

Soft PVC and PET bar code label often has exudation of plasticizer which is also known as squeeze-out. When choosing PET and PVC bar code label, we should pay more attention to choose the water-based glue. Hot-melt glue is easy to overflow.

9、According to your bar code label size

When not sure whether the bar code paper size is appropriate, we must pay attention to the actual test, to prevent the case of buying back but can not be used.

10、Do labeling machine test

Before purchasing the bar code label, it is necessary to place the bar code label into the automatic labeling machine for several actual tests to check the labeling fluency and other conditions.

Bar code label is necessary for all major businesses. In fact, the selection of bar code label is not simple. Most of the time, poor quality bar code label is selected. It is important for us to gather some information and learn some knowledge in advance before we purchasing bar code label so that we can avoid to purchase the worse one. Necessary purchasing skills of high temperature resistant adhesive manufacturer should be mastered.

Post time: Nov-18-2022