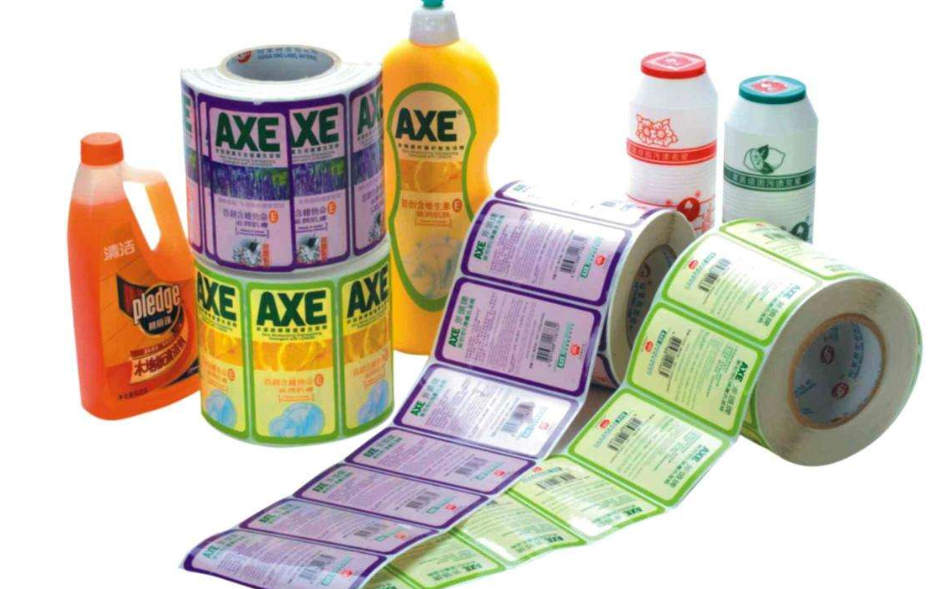

1. Label sticker printing process

Label printing belongs to special printing. In general, its printing and post-press processing are completed on the label machine at one time, that is, multiple processing procedures are completed in several stations of one machine. Because it is on-line processing, the quality control of self-adhesive label printing is a comprehensive printing and processing problem. It must be comprehensively considered and implemented from the selection of materials, the configuration and regulation of equipment, and the formulation of process routes.

When choosing raw materials, be sure to use high-quality self-adhesive materials with qualified physical and chemical indicators, instead of using expired or unstable physical and chemical indicators. Although the latter is low in price, the quality of such materials is unstable and consumes a lot in various processes, and even causes the equipment to fail to process normally. While wasting raw materials, it also wastes a lot of manpower and material resources. As a result, the processing cost of finished labels not necessarily low.

2.Prepress processing

In terms of pre-press processing, many orders designed by customers are mainly offset printing or gravure printing. If this kind of manuscript is printed with flexographic printing, the sample will have many quality problems, such as inadequate colors, unobvious levels, and hard Wait. Therefore, to solve such problems, timely communication before printing is very necessary.

Post time: Sep-01-2020