Glazing process can be applied to the surface coating of all kinds of materials. The purpose is to increase the glossiness of the printed matter surface to achieve the function of anti-fouling, anti-moisture and protection of pictures and texts.

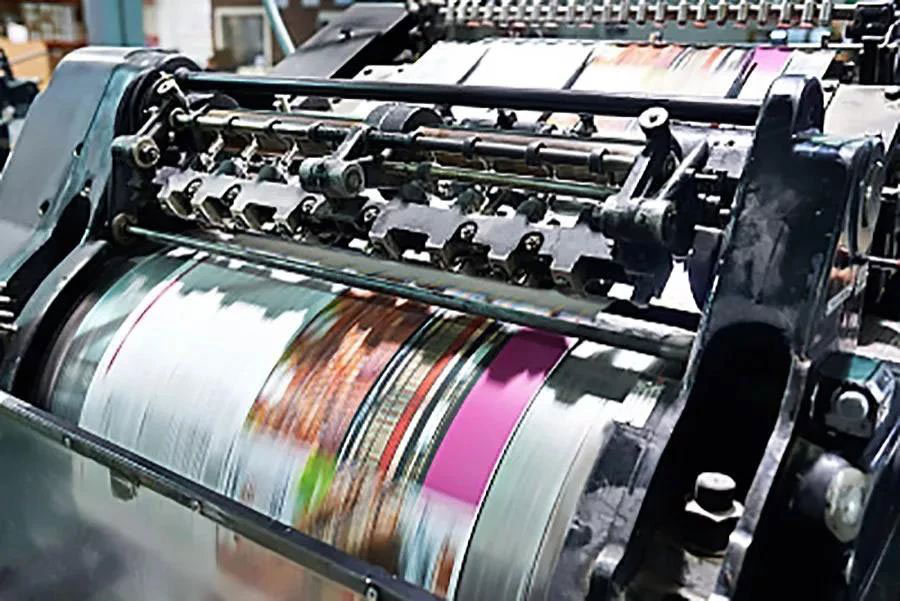

Sticker glazing is generally carried out on a rotary machine, improper handling, often appear label bending, light oil dry and a series of problems.

Question 1:Why does the label bend after glazing? How to solve?

Reason 1: The glazing is too thick. UV curing glazing film shrinkage, and the plastic film basically does not shrink, this causes the shrinkage between the two is not consistent, eventually lead to label bending deformation

Reason 2 : Not special glazing, shrinkage is too large, so that the label bending

Solution:Select the appropriate anilox roll, 500~700 lines/inch, replace the original anilox roll on the machine.In addition, the choice of special, small shrinkage oil, in order to reduce the film deformation.

Question 2:What is the cause of UV varnish drying after glazing? How to solve?

Reason 1: Glazing oil is too thick, the normal UV curing power can not make it curing dry

Reason 2:Printing speed is too fast, resulting in UV varnish curing time is too short, not dry.

Reason 3: UV varnish failure or photosensitive degree reduction, resulting in slow curing rate

Reason 4:UV lamp aging, power reduction, resulting in light oil curing incomplete.

Solution:At first, it operates at a low speed under the condition of using the fine wire aniline roller. Check whether color ink is dry, and then at the speed of 10m, 20m, 30m per minute, and separately with tape to check whether the varnish can be stuck. It is recommended that in-mold label UV glazing speed not exceed 40m per minute.

Post time: Aug-24-2020